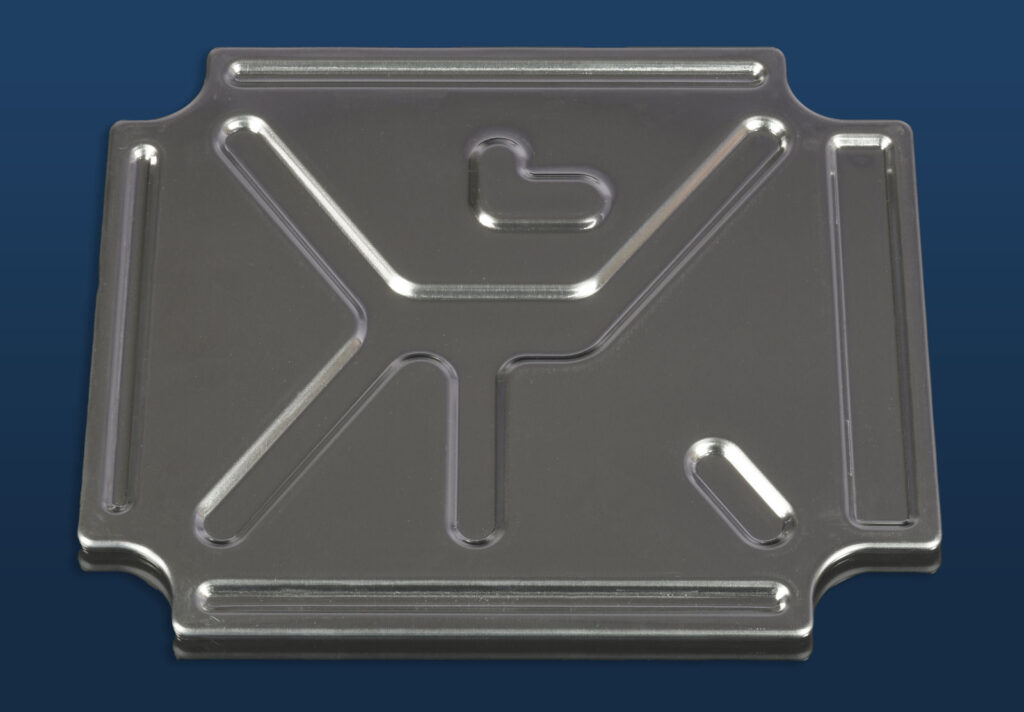

ECU Covers

1.5m manufactured per annum

Electronic Control Units (ECUs) Are Crucial in Today’s Complex Automotive Environment.

An Electronic Control Unit (ECU) is a microprocessor-based device that manages and controls various vehicle functions – such as engine operation, safety systems, and comfort features.

These ECUs, each powered by dedicated chips and software, are the brains behind nearly every electronic aspect of modern vehicles, controlling over 100 different systems to ensure seamless operation and connectivity.

Recognising the critical role of ECUs, Clamason excels in crafting precision-engineered covers that safeguard these vital components against environmental challenges, ensuring their optimal performance and longevity.

ECU Covers for Performance and Protection

The quality of an ECU’s internal wiring is essential, but so is the casing that protects it from environmental hazards.

Pressed metal covers and housings offer robust protection, superior electromagnetic interference (EMI) shielding, and optimal heat dissipation- safeguarding the ECU from moisture, dust, and other dangers.

Clamason’s Cutting-Edge Metal Pressing Solutions

At Clamason, we specialise in producing ECU covers and housings that meet the demanding standards of the automotive industry.

Our advanced metal pressing capabilities allow us to work with a variety of steels and non-ferrous metals, delivering products that adhere to extremely tight tolerances.

Why Choose Clamason for ECU Covers?

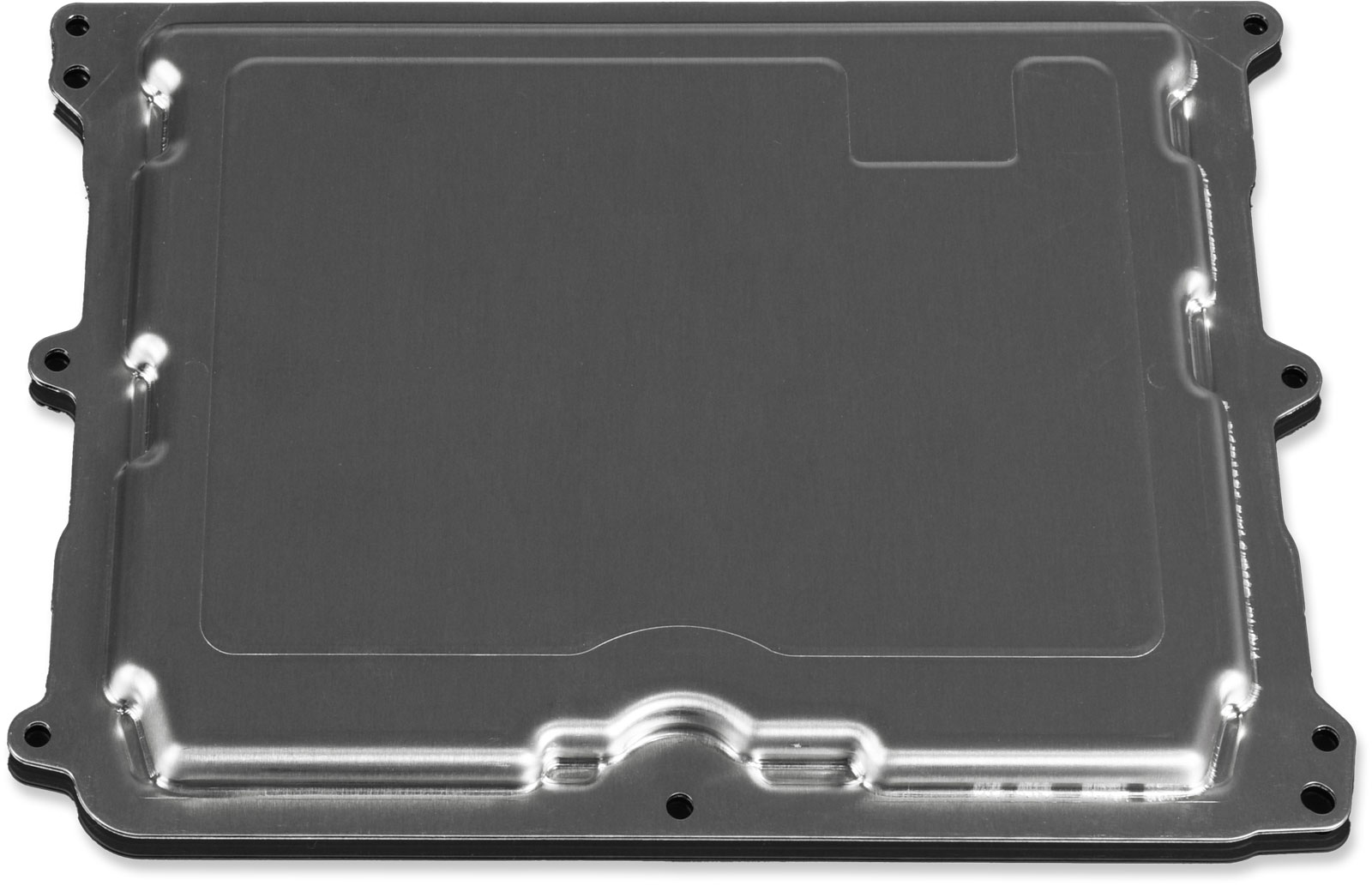

- Diverse Materials and Precision. Our expertise spans a range of metals, with thicknesses from 0.8mm to 3.5mm, ensuring durability and performance. The main materials Clamason manufacture ECU covers from are 3000 & 5000 series aluminium in varying temper grades depending on the component requirements.

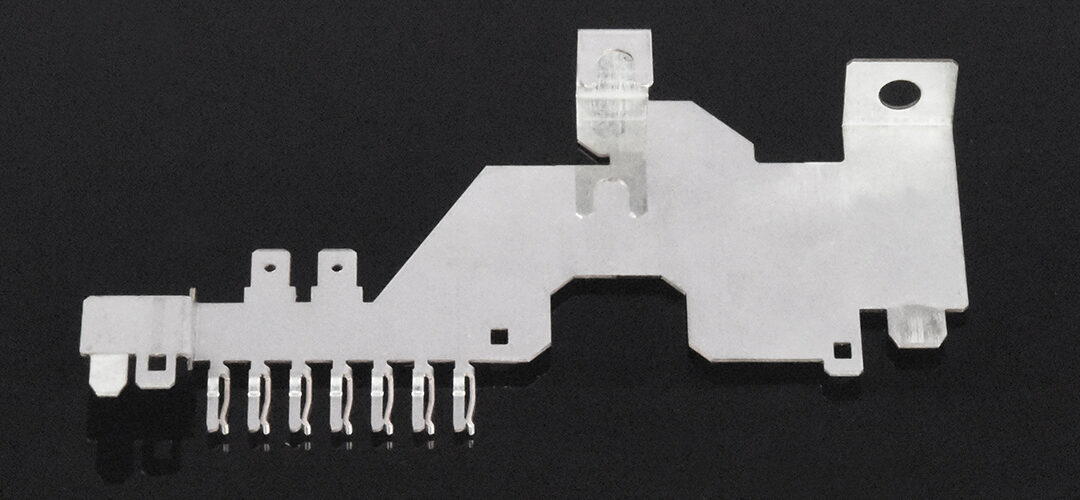

- Advanced Manufacturing Techniques. Depending on customer requirements, components are crafted using progression tooling, which can include in tool transfer and additional features like coining to minimise cutting burr.

- State-of-the-Art Cleaning. Critical components undergo thorough cleaning using our technical cleaning machines, ensuring the highest standards of cleanliness and performance.

Advanced Equipment for Unmatched Quality

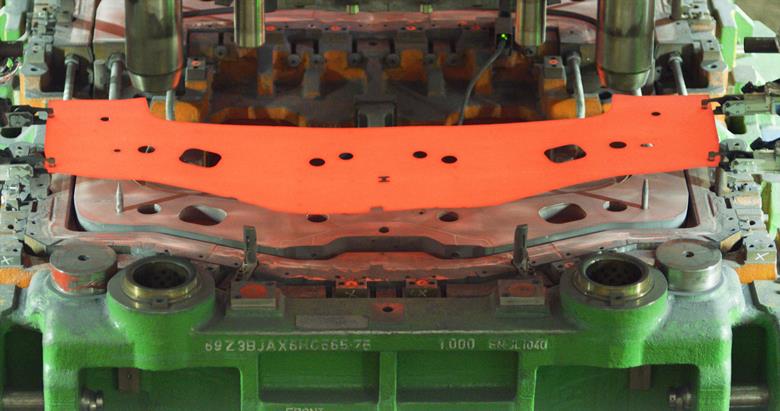

Clamason’s commitment to excellence is underscored by our investment in industry-leading technology, such as the GTX 400 400T press and the ATC100 technical cleaning process. These investments reflect our dedication to offering industry-leading equipment for metal stamping projects, especially for the electric and hybrid vehicle market.

400T Press: Our latest acquisition from the GTX series, developed by Chin Fong in Taiwan, features a full stamping line with new decoiling and straightening technology.

The GTX400 press can run progression tooling up to 3.4 meters long which can be required to produce complex ECU covers. This is used to multiple progression & transfer stages to achieve the complex components features and critical tolerances.

ATC100 Technical Cleaning: Designed to meet the challenges of hybrid and electric vehicle component manufacturing, the ATC100 process – developed in partnership with PERO – ensures best-in-class component cleanliness.

It addresses the critical need for bonding silicon surfaces and removing metallic particles that could cause short circuits, setting new standards in component cleanliness.

At Clamason, we don’t just manufacture components. We deliver solutions that drive automotive innovation forward.

With our advanced metal pressing capabilities, commitment to quality, and state-of-the-art cleaning processes, we are ready to support your next project.

Contact us today to learn how our expertise in ECU covers and housings can enhance your automotive manufacturing goals.

Case Studies

Fire plates, Part of a Life Saving Device for the Construction Industry

Introduction Clamason Industries, a leader in precision metal stamping and assembly, began their collaboration with ViperClip to help develop a vital fire safety component for the ViperClip system. The ViperClip, an innovative cable fastening solution designed by...

Clamason Help Blue-Chip Manufacturer Restore Production Cycle

The Challenge During the height of the COVID-19 pandemic, a major blue-chip manufacturer of electrical assemblies found themselves in difficulty. Their usual stamping solution was no longer fit for purpose, with technical and supply issues blighting the production...

Advanced High Strength Steels (AHSS)

Taking Shape Most advanced-high-strength steels (AHSS) materials comprise specific chemical compositions and microstructures, with a number of strengthening mechanisms used to boost strength, ductility, toughness and fatigue properties. While such characteristics are...

Solvent Degreasing Works for Clamason

Pero degreaser meets SED legislation & slashes solvent use at volume pressings manufacturer Established 60 years ago, Clamason Industries is a highly service-orientated, independent UK manufacturer and assembler of precision pressings serving a broad spectrum of...

Latest News

Metal Cleaning & Contract Services Infographic

Thin Gauge Stainless Steel Pressing: Is It Right For Your Project?

Thin Gauge Stainless Steel Pressing: Is It Right For Your Project? Manufacturers working in the medical, automotive, electronics and consumer goods sectors use thin gauge stainless steel primarily because it provides strength along with formability and corrosion...

How Does High Precision Metal Pressing Improve Accuracy?

In industrial sectors where even the smallest deviation in precision can jeopardise safety, functionality, or performance, manufacturing accuracy is vital. This ability to maintain quality and consistency is especially relevant in...

Ensuring Regulatory Compliance in Metal Stamping for Medical Devices

Stamping Regulations Metal stamping, a key process in the production of medical devices, must adhere to stringent regulatory standards to meet industry requirements. Here we will examine the importance of regulatory compliance in metal stamping for medical devices,...

Discover more about our Metal Stamping and Presswork for Automotive Industry