Presné lisovanie a razenie

Clamason, líder na trhu už viac ako 70 rokov, je vaším full-service partnerom pre vývoj a výrobu presných výliskov.Sektory

V spoločnosti Clamason pomáhame lídrom v odvetví inovovať a vyvíjať prostredníctvom výnimočne vyrobených komponentov. Aby sme to dosiahli, spolupracujeme s globálnymi zákazníkmi na podpore projektov všetkých veľkostí, od prototypu až po výrobu. Vďaka našim dlhoročným skúsenostiam v oblasti dizajnu a lisovania kovov sú naši inžinieri počas procesu projektovania produktov mimoriadne kreatívni a vždy hľadajú príležitosti na poskytovanie pridanej hodnoty a úspory nákladov pre našich klientov vo všetkých našich cieľových sektoroch.

Tieto sektory zahŕňajú:

Automobilový priemysel

Lekárska

Priemyselný

Eco Tech

Poprední technici v oblasti lisovania a razenia kovov

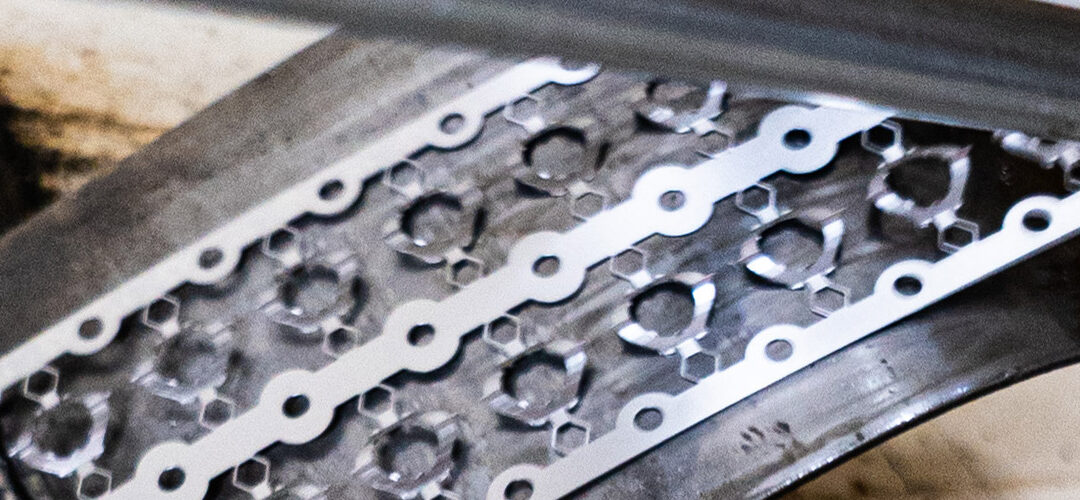

Clamason sú medzinárodne uznávaní odborníci na presné lisovanie a razenie. Naše inovatívne a neustále sa rozvíjajúce inžinierske schopnosti umožňujú našim zákazníkom ťažiť z včasnej a efektívnej výroby komponentov s dokonalosťou očakávanou od každého výstupu. Naša odbornosť pokrýva celý rad služieb presného lisovania a razenia, vrátane:

Dizajn

Projektový Manažment

Špecialisti na výrobu nástrojov

Výlisky / Výlisky

Technické čistenie

Výroba pre ekologickú technológiu

Najnovšie Správy

Ako vysoko presné lisovanie kovov zlepšuje presnosť?

V industrijskih sektorjih, kjer lahko že najmanjše odstopanje v natančnosti ogrozi varnost, funkcionalnost ali zmogljivost, je natančnost izdelave ključnega pomena. Ta sposobnost ohranjanja kakovosti in doslednosti je še posebej pomembna na področjih, kot so...

Zabezpečenie súladu s predpismi v oblasti lisovania kovov pre zdravotnícke pomôcky

Predpisy o lisovaní Lisovanie kovov, kľúčový proces pri výrobe zdravotníckych pomôcok, musí spĺňať prísne regulačné normy, aby sa splnili priemyselné požiadavky. Tu sa pozrieme na dôležitosť dodržiavania predpisov pri lisovaní kovov pre zdravotnícke pomôcky a na kroky...

Prehľad presného inžinierstva spoločnosti Clamason vo výrobe zdravotníckych pomôcok

Väčšia zložitosť vyžaduje väčšiu presnosť Presné inžinierstvo je nevyhnutné pri výrobe zdravotníckych pomôcok kvôli špeciálnej povahe príslušných produktov. Zdravotnícke zariadenia, od autoinjektorov až po inhalátory suchého prášku, vyžadujú veľkú pozornosť pri...

Úloha kovových komponentov v zariadeniach na podávanie liekov

Kov funguje skvele Zariadenia na podávanie liekov spôsobili revolúciu v tom, ako berieme lieky, vďaka čomu je liečba efektívnejšia, presnejšia a príjemnejšia pre pacienta. Tieto zariadenia siahajú od jednoduchých mechanických systémov až po veľmi zložité elektronické...

Prečo Clamason?

Naši inžinieri budú spolupracovať s vaším tímom už v počiatočnej fáze návrhu, pričom použijú pokročilé technológie na výrobu presných nástrojov rýchlo, efektívne a s minimálnym odpadom.

Máme akreditáciu ISO9001, ISO13485, ISO14001 a IATF16949, čo vám dáva istotu, že naše znalosti a kvalita procesov budú zodpovedať špeciálnym potrebám vašich zariadení. Podobne máme bohaté skúsenosti s jedinečnými vlastnosťami kovov, ako je nehrdzavejúca oceľ, čo nám umožňuje robiť vysoko efektívne a nízkorizikové rozhodnutia v súvislosti s dizajnom a výrobou vášho produktu.

Tiež rozumieme tomu, ako najlepšie čistiť, manipulovať a baliť presné kovové výlisky pre váš priemysel, čo nám umožňuje poskytnúť jediný systém s uzavretou slučkou pre celý výrobný cyklus vášho komponentu.

Ste pripravení zistiť viac?