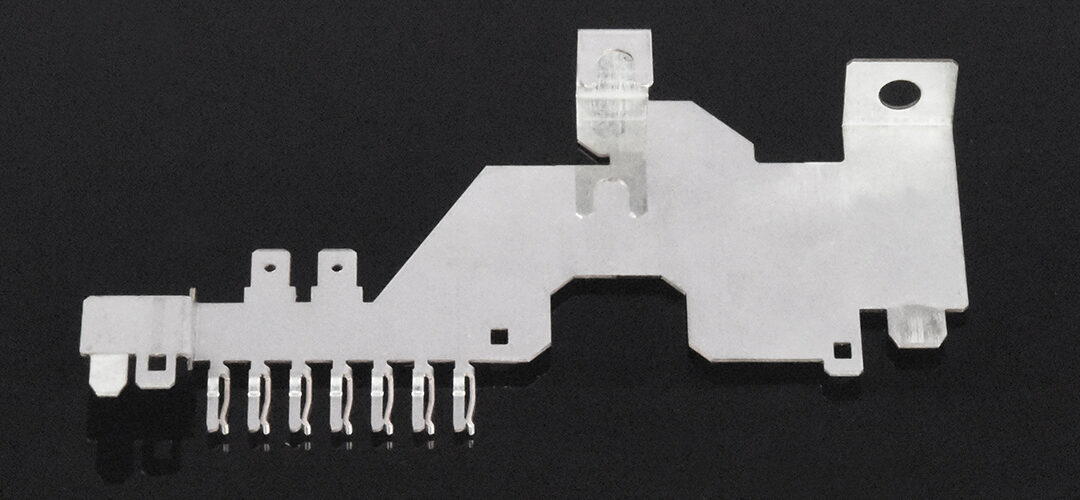

Precision Metal Stamping and Presswork Specialists

A market leader for over 70 years, Clamason are your full-service partner for the Development and Manufacture of precision pressings.Our Key Sectors

At Clamason, we help industry leaders to innovate and develop through exceptionally manufactured components. To achieve this, we partner with global customers to support projects of all sizes, from prototype to production. Using our many years of design and metal pressing engineering experience, our engineers are extremely creative during the product design engineering process, always looking for opportunities to deliver added value and cost savings for our clients across all our target sectors.

These sectors include:

Automotive

Medical

Industrial

Eco Tech

Full-service Metal Stamping Manufacturers

Clamason are internationally recognised precision pressing and stamping experts. Our innovative and continuously evolving engineering capabilities allow our customers to benefit from timely and efficient component production, with excellence expected from every output. Our expertise covers the full house of precision pressing and stamping services, including:

Metal Stamping & Presswork Services

Project Management

Tooling

Design

Technical Cleaning

Manufacturing for New Eco Technology

Latest News

Metal Cleaning & Contract Services Infographic

Thin Gauge Stainless Steel Pressing: Is It Right For Your Project?

Thin Gauge Stainless Steel Pressing: Is It Right For Your Project? Manufacturers working in the medical, automotive, electronics and consumer goods sectors use thin gauge stainless steel primarily because it provides strength along with formability and corrosion...

How Does High Precision Metal Pressing Improve Accuracy?

In industrial sectors where even the smallest deviation in precision can jeopardise safety, functionality, or performance, manufacturing accuracy is vital. This ability to maintain quality and consistency is especially relevant in...

Ensuring Regulatory Compliance in Metal Stamping for Medical Devices

Stamping Regulations Metal stamping, a key process in the production of medical devices, must adhere to stringent regulatory standards to meet industry requirements. Here we will examine the importance of regulatory compliance in metal stamping for medical devices,...

Why partner with Clamason?

Our engineers will work with your team early in the design phase, using advanced technology to produce precision tooling quickly, efficiently and with minimal waste.

We’re ISO9001, ISO13485, ISO14001 and IATF16949 accredited, giving you the assurance that our knowledge and quality of processes will match the specialist needs of your devices. Similarly, we have extensive experience with the unique properties of metals such as stainless steel, allowing us to make highly effective and low-risk decisions in regard to the design and manufacture of your product.

We also understand how to best clean, handle and package precision metal stampings for your industry, allowing us to provide a single, closed loop system for the entire production cycle of your component.

Ready to find out more?