In industrial sectors where even the smallest deviation in precision can jeopardise safety, functionality, or performance, manufacturing accuracy is vital. This ability to maintain quality and consistency is especially relevant in...

In industrial sectors where even the smallest deviation in precision can jeopardise safety, functionality, or performance, manufacturing accuracy is vital. This ability to maintain quality and consistency is especially relevant in...

Stamping Regulations Metal stamping, a key process in the production of medical devices, must adhere to stringent regulatory standards to meet industry requirements. Here we will examine the importance of regulatory compliance in metal stamping for medical devices,...

Greater complexity requires greater precision Precision engineering is essential in the manufacture of medical devices due to the special nature of the products involved. Medical devices, from auto-injectors to dry powder inhalers, require great attention to detail...

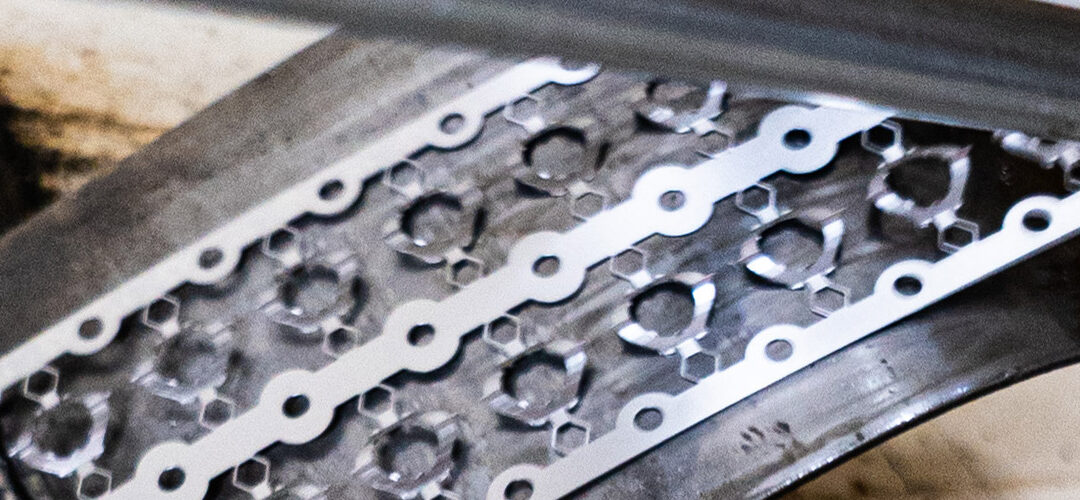

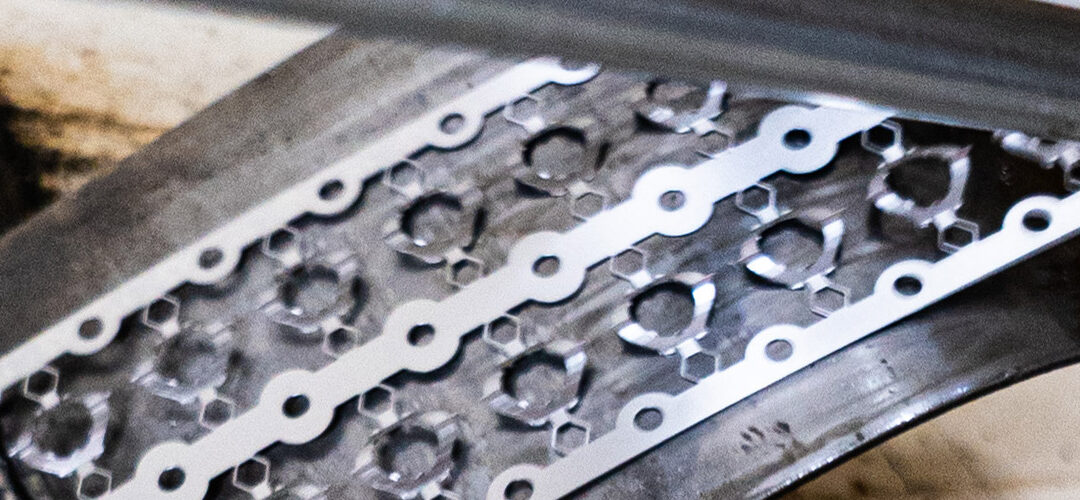

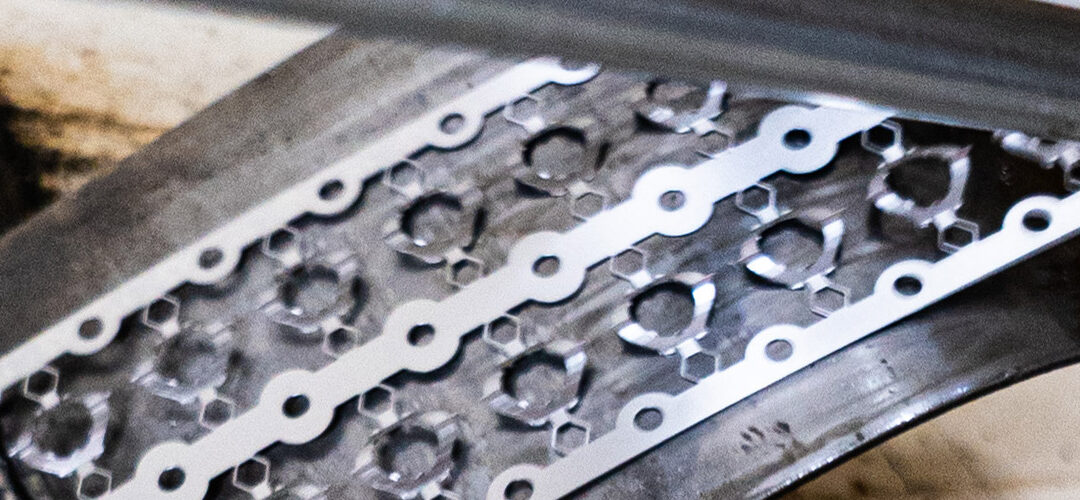

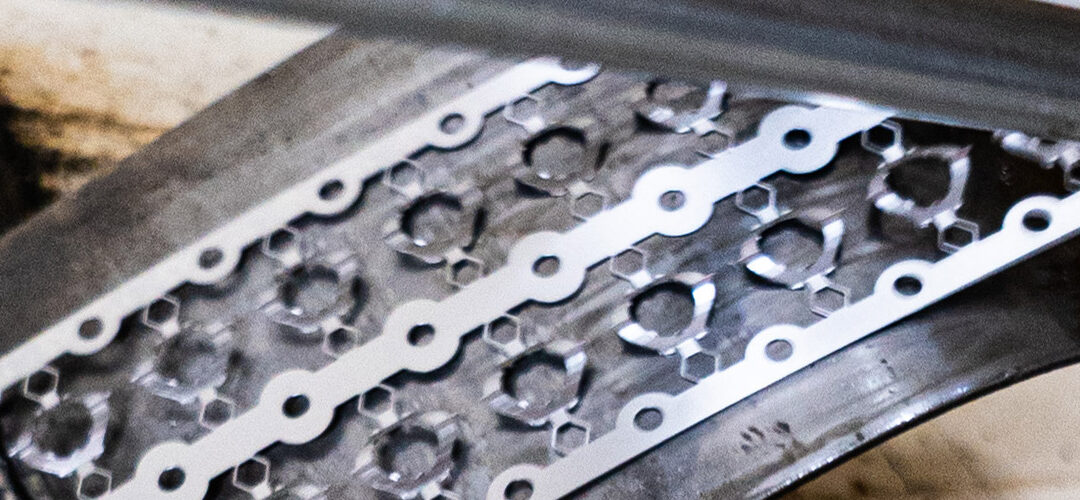

Metal Works Brilliantly Drug delivery devices have revolutionised how we take medication, making treatment more effective, accurate and patient-friendly. These devices range from simple mechanical systems to highly complex electronic devices. A critical aspect of...

Metal stamping plays a huge role in the production of high-quality medical devices, providing precision, efficiency, and reliability. As the medical industry changes, so too does the tech and methods behind metal stamping. Here we’ll examine the latest innovations...

Perfect SimulationAs the need for high-quality medical components continues to rise, manufacturers are constantly looking for new ways to improve the design and production process. One such method is stamping simulation. This advanced technique offers numerous...

The Proof is in Precision Manufacturing for the medical industry needs a special kind of precision. The importance of efficiency, accuracy, and consistency are often measured on a microscopic level and need to be 100% accurate. One method that has revolutionised this...

High-Speed PressingsThe medical device industry is rightly defined by its insistence on precision, quality, and reliability. As the demand for advanced medical devices grows, manufacturers are always looking for new ways to improve. One such idea is the use of...

Precision Cleaning Technical cleaning is a big part of manufacturing that ensures efficiency, reliability, and longevity of machinery and components. The process involves removing contamination that can impede the performance of equipment, lead to premature wear, or...

Compliance Counts Maintaining high standards and complying with international regulations is a major part of today’s manufacturing landscape. We’re proud to see our European site, Clamason Slovakia, is working hard towards achieving ISO13485 accreditation, testament...

The Forefront of Medical Manufacture Established in 1947, Clamason has established itself as a leading provider of critical components. More recently their dedicated medical team has moved to the forefront of design. The team has proved especially innovative in the...

Hygiene: A Top Priority Technical cleaning processes are a big factor in making sure components meet stringent hygiene and quality standards required by the medical industry. Here we’ll explore the critical role that technical cleaning plays in medical component...