The Forefront of Medical Manufacture

Established in 1947, Clamason has established itself as a leading provider of critical components. More recently their dedicated medical team has moved to the forefront of design. The team has proved especially innovative in the manufacture of Rigid Needle Shield Removers (RNS) and medical springs. These components play a big part in ensuring the safety and efficacy of larger medical devices, and Clamason’s expertise in this field is testament to their commitment to quality, excellence and safety.

The Integration of Rigid Needle Shield Removers

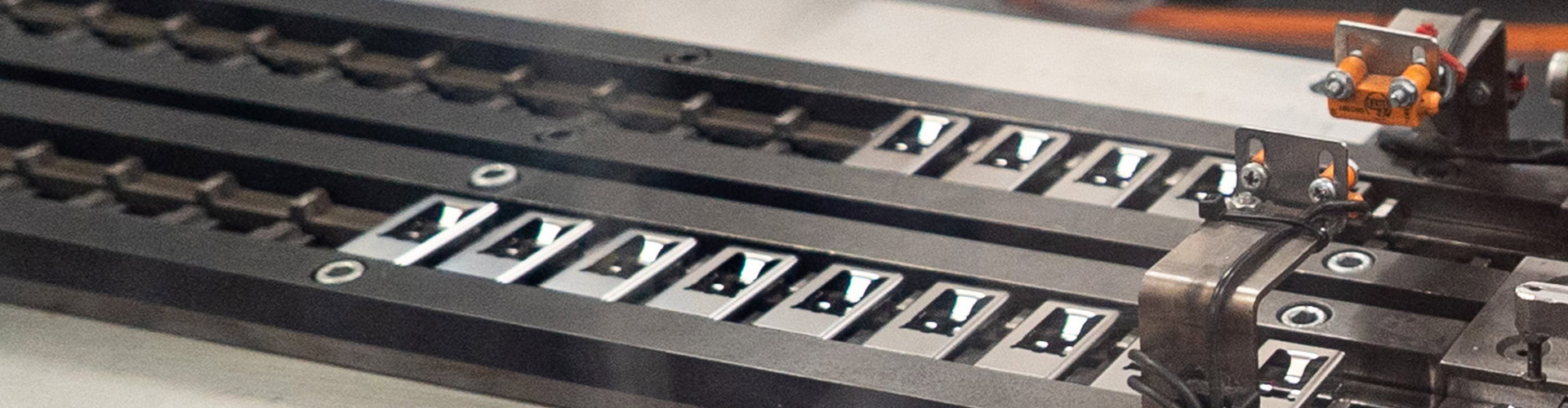

Rigid Needle Shield Removers are essential components in the medical and pharmaceutical industries. They are designed to safely and effectively remove the needle shield from syringes and other needle-based devices, ensuring the needle remains sterile and undamaged until the moment of use. The company employs advanced manufacturing techniques and stringent quality control measures to produce RNS components that meet the highest industry standards. Each piece is crafted with careful attention to detail, ensuring it performs flawlessly in critical medical applications.

Advanced Manufacturing Techniques

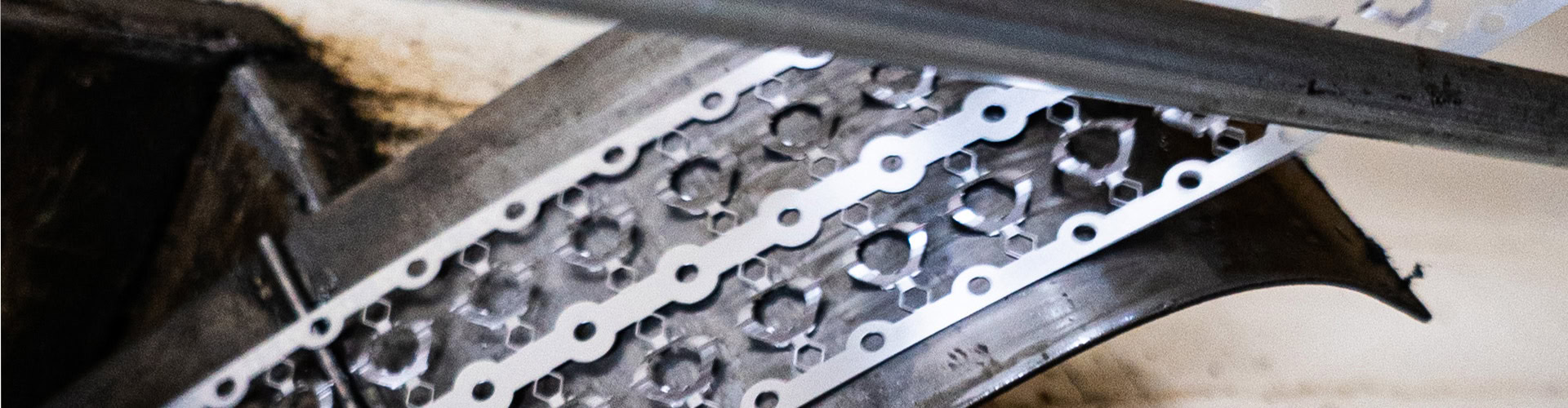

The manufacturing process for RNS and medical springs at Clamason involves cutting-edge technology and highly skilled engineers. The company uses the latest machinery and equipment to engineer the highest levels of precision and, just as importantly, consistency. This includes high-speed stamping presses, precision tooling, and advanced quality inspection systems. One big advantage of Clamason Industries is the ability to produce complex components with tight tolerances. This is important for medical springs, which often require intricate design and precise load characteristics. Clamason’s experience and knowledge in this area makes sure each spring meets the exact specifications required for flawless operation.

Quality Counts

The company adheres to strict quality control protocols at every stage of the manufacturing process, from raw material selection through to final inspection. This commitment to quality is reflected in their ISO 9001 and ISO 13485 certifications, which demonstrate a dedication to meeting the highest standards of quality and regulatory compliance. To ensure the reliability of their RNS and medical springs, Clamason conducts extensive testing and inspection. This includes mechanical testing to verify the strength and durability of each component, as well as dimensional inspections to make sure every piece meets the required tolerances.

Continuous Improvement

The company is constantly exploring new technologies and processes to improve the quality and performance of their products. This dedication to innovation is clear through continuous investment in research and development, along with partnerships with leading medical device manufacturers. Clamason’s focus on continuous improvement extends to all aspects of operations. The company regularly reviews and updates their manufacturing processes to incorporate the latest advances in technology and best practice. One of the key strengths of Clamason is the ability to offer customised solutions. The company works closely with customers to understand their specific requirements and develop bespoke solutions that address their challenges. This includes designing and manufacturing special RNS and medical springs, all optimised for their intended applications. Clamason’s flexibility and agility are critical in medicine, where timelines and specifications can change rapidly. The company’s agile manufacturing capabilities enable fast adaptation to new requirements and timely delivery of high-quality components. This methodology has established Clamason as a dependable and reputable partner within the medical device sector.

It’s Good to be Green

In addition to their technical expertise, Clamason is committed to sustainability and environmental responsibility. The company recognises the importance of minimising environmental impact and has implemented a range of initiatives to reduce waste, conserve energy, and promote sustainable practices. Clamason’s environmental management system is certified to ISO 14001, demonstrating a real commitment to environmental stewardship. The company actively seeks to reduce their carbon footprint and minimise the use of hazardous substances in their manufacturing processes. By prioritising sustainability, Clamason is not only contributing to a healthier planet but also meeting the growing demand for environmentally responsible products. Clamason’s ability to provide customised solutions and their dedication to sustainability further enhances their reputation as a leader in the field. Clamason is well-positioned to meet the challenges of the future and continue to provide critical components that ensure the safety and efficacy of medical devices worldwide.