Greater complexity requires greater precision

Precision engineering is essential in the manufacture of medical devices due to the special nature of the products involved. Medical devices, from auto-injectors to dry powder inhalers, require great attention to detail during production. These often life-saving devices must meet strict quality standards to ensure safety and effective patient outcomes.

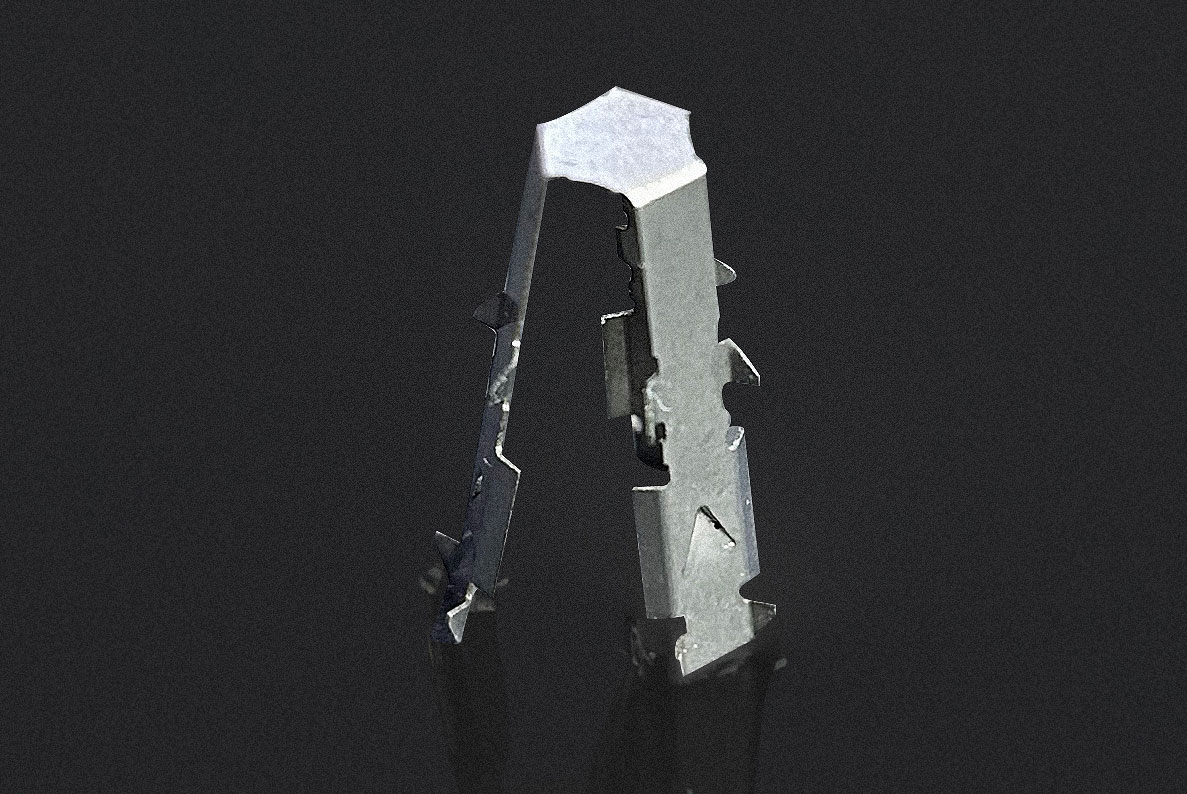

The ability to produce components with extremely tight tolerances is crucial for the medical industry. For example, components must be consistent to ensure accurate drug delivery and patient safety. Precision engineering ensures that every part is manufactured to exact specifications, eliminating the risk of failure. Clamason uses state-of-the-art manufacturing techniques to achieve the highest level of precision. One such technique is metal stamping, which enables the production of intricate and complex components with consistent microscopic precision. This method is particularly suitable for the production of large volumes of small detailed parts commonly used in medical devices.

Another aspect of Clamason’s manufacturing process is the use of progressive dies. These specialized tools enable the efficient production of complex parts by performing multiple operations in a single pass through the die. This not only speeds up the production process, but also reduces the possibility of errors.

Quality control and compliance

It goes without saying that QC is an aspect of manufacturing that is extremely important. Clamason uses strict quality control measures throughout the manufacturing process to guarantee that each component meets the required specifications. This includes comprehensive testing and inspection throughout production, from raw materials to final product verification. Advanced inspection techniques such as coordinate measuring machines (CMMs) and optical inspection systems are used to verify component dimensions and integrity. These machines provide accurate and detailed measurements, ensuring that any deviations from specifications are immediately identified and corrected.

Compliance with industry standards and regulations is another critical aspect of quality control. The medical device industry is highly regulated with strict guidelines governing product design, manufacturing and testing. Clamason adheres to these regulations to the letter and ensures that their manufacturing processes meet the highest possible standards.

Innovations in the production of medical devices

The main area of new thinking is the use of advanced materials in the production of medical devices. Materials such as titanium and stainless steel are common today due to their biocompatibility and strength. However, newer materials such as shape memory alloys and biopolymers are being explored for their unique properties, such as the ability to change shape in response to a change in temperature or to degrade safely in the body.

Cooperation with the medical industry

The successful production of medical devices requires close cooperation with experts in the field of medicine. This ensures that the products developed meet the specific and demanding needs of the healthcare sector. Clamason works closely with industry experts to provide engineering support and expertise throughout design and development. This approach enables early identification of potential design and manufacturing challenges, enabling solutions to be found and implemented before full-scale production begins. This cooperation ensures that the final product is not only of the highest quality, but also adapted to specific requirements.

The best is yet to come

The future of precision engineering in medical device manufacturing looks promising, with constant advances in technology and materials driving innovation at an amazing rate. Increasing demand for minimally invasive surgery, personalized medicine, and wearable medical devices is expected to drive growth in this sector. As the industry evolves, Clamason remains committed to providing superior solutions that meet the highest standards of precision and quality. A true commitment to innovation, quality control and collaboration positions them as a key player in the future of medical device manufacturing.

Through advanced manufacturing techniques, strict quality control and a commitment to innovation, Clamason continues to be a leader in providing precisely engineered solutions that meet the evolving needs of the medical industry.