The wait is finally over, as Clamason’s new 400T press has been successfully installed at our Slovakian plant.

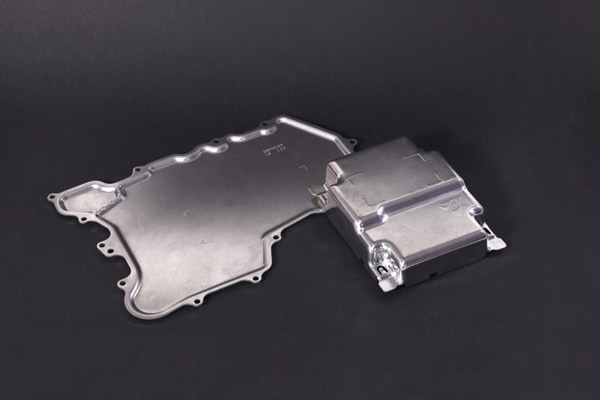

These newly released images show the cutting-edge machinery in situ in Ratislavova, where it is set to have a huge impact on production.

As a business, Clamason have always invested in industry leading equipment as a means of offering OEMs the very best technology to assist in metal stamping projects.

Our newest acquisition is the latest in a long line of high speed and high precision mechanical presses stemming from the coveted GTX series.

Developed by Chain Fong in Taiwan, our new press boasts a full stamping line, complete with new decoling and straightening technology.

Allowing us to realise larger tooling to produce finished parts using a single progression tool, it will make a huge difference to output that is growing ever more complex.

A growing demand for intricate components linked to the electric and hybrid vehicle market in particular, will now be readily satisfied.

Clamason purchased the 400T press from long-standing partners Worcester Presses, with whom we’ve enjoyed a 30-year relationship.

Sales Director Ian Davies elaborated on the difference it’s set to make.

“We’re delighted to finally have the TX 400 up and running”, said Davies. “We have no doubt it will lead to improve flexibility and better stamping quality. What’s more it will facilitate prolonged tool life, creating long-term value across multiple production cycles.”

Stay tuned for further updates on the new machine, along with a wider expansion of the company.