Electronic components are often highly complex and produced in their millions, ready to be used in a wide range of consumer products.

When specifying a new component, it’s vital that OEMs strike the perfect balance of design flexibility, production capacity and cost per part. Often, metal die casting is considered the process of choice, due to its ability to:

- Manufacture complex net shapes

- Keep quality consistent over large volumes

- Achieve tight tolerances

- Produce components with fast cycle times.

However, die casting isn’t the only way to produce complex parts at scale. For many designs, metal stamping can achieve all the benefits of a cast part – with plenty more advantages that a casting process may struggle to accomplish.

If you’re considering a re-design of your electronic component but aren’t sure if you should take the plunge, read on…

Switching to a pressed part can save you money.

… Yes, really. Even when you consider new tooling.

Casting requires high temperatures to create molten metal. By contrast, stamping is entirely cold-form – removing the need to rely on heat. This means that large sums can be saved on production, purely because the process of stamping metal isn’t underpinned by intense energy use.

When the total cost-per-part is slashed, you can make a quick return on what you spent on a tooling re-design. In fact, Clamason customers have seen this expenditure recouped in just one year – opening the door to improved ROI in the years that follow.

Press tools require less ongoing maintenance than castings.

A casting will require dies that are refurbished regularly, often after a few thousand parts have been produced. Of course, you could be creating electronic components in batches of millions – so, these refurbs can consume a sizeable chunk of your budget.

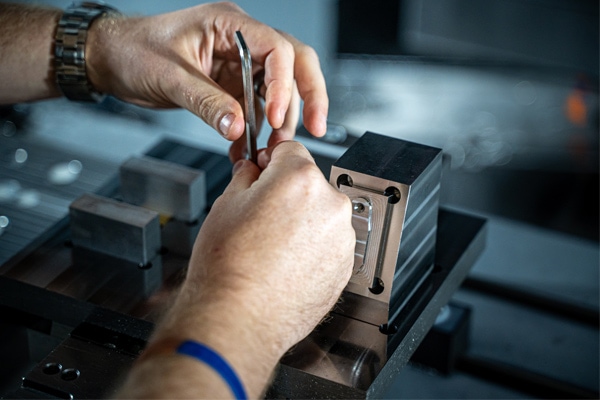

By contrast, a press tool will frequently produce millions of parts before needing refurbishment, making it far better suited to large-scale production. In addition, electronic components that are from metal stampings will be ready for assembly, straight off the press. This will also save you money on additional services, such as surface finishing, which are common in the casting process.

Pressed parts are better for the environment.

Is your company working towards eco initiatives and accreditations, such as Ecovadis?

If so, switching production from cast to press could mean using far less energy – creating a green, lean process for your electronic components.

As discussed earlier, the casting process requires huge amounts of heat. By switching to cold-form technology for metal pressings, energy use is significantly cut – which not only helps to protect the planet, but shrink your energy costs, too.

We can take the stress out of re-designing your electronic component.

At Clamason, our CAD specialists use industry-leading software to design bespoke metal pressing solutions to suit your exact specifications.

Whether it’s a brand-new concept or an enhancement to an existing component (such as re-purposing a design from cast to press), we’re focussed on maximising value and reducing costs.

There’s no need to worry about heavy investments that may not come to fruition. The feasibility and performance of your component will be accurately analysed before production, including the identification of optimum processes and materials.

Our aim is to help you re-design your electronic component into a pressed part that is higher quality, cheaper to produce and better for the environment than the cast equivalent.

Our experienced team have all the knowledge and problem-solving skills required to find the right solution, at the right price. So, feel free to get in touch today and explore the opportunity to re-design your cast products for a more efficient, pressed alternative.