When sourcing electronic components in bulk, it’s tempting to work with an offshore manufacturer who can offer the cheapest price. However, the advantages aren’t always what they seem.

As a market leader in the development and manufacture of precision pressings, we’ve worked with countless OEMs in the consumer electronics sector. Whether we’ve worked on their project from the get-go or helped them to reshore production from elsewhere, our expert teams in the UK and Europe are well-versed in the differentials between a local and overseas production.

With huge increases in transport costs and mounting pressure for reduced lead times, the appeal of shipping components from the other side of the world is waning. With this in mind, here’s five reasons why manufacturing your electronic components in the UK might be the best bet for your business.

1. Flexibility

The fast-moving consumer electronics market is constantly evolving. Along with the opportunities, this can present some challenges – such as having enough time to market products, while also having the scope to make last-minute changes.

Orders of electronic components are often in the millions and for many overseas suppliers who sell themselves on price, you’ll be held to a minimum order quantity.

Local suppliers who are quality-driven, however, will allow you to flex down and support smaller volumes – so you won’t lose money if you suddenly need to reduce supply.

2. Better Lead Times

Few OEMs can risk production delays. You need your components to arrive on schedule and to specification, every time.

When you’re relying on a supplier that’s half a world away, shipping can be a gamble. There can be import or export restrictions, complex documentation requirements and an increased risk of loss or delay during long-distance transit.

Ultimately, large overseas shipments can be slow and complicated when you simply don’t have the luxury of time – and this assumes that your shipment will be entirely correct when you eventually receive it.

By using a local supplier, you’ll cut the arduous red tape associated with international imports and exports, as well as slashing delivery times to as little as 24 hours – keeping supply chain logistics smooth, cost-effective and reliable.

3. High Quality From The Start

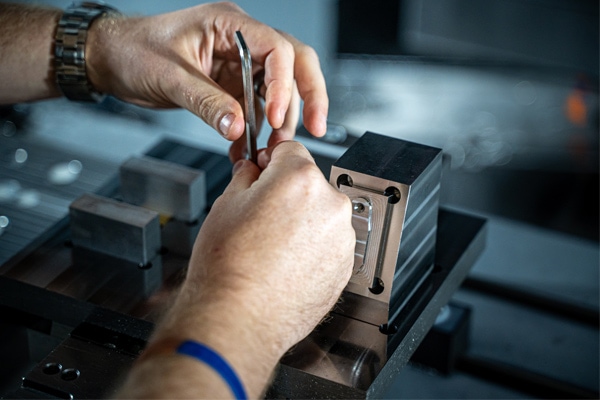

Pressed electronic components are generally produced on progression tooling to enable extremely high volumes. Batches that don’t meet your standards will need to be re-worked, resulting in huge production delays and costs across thousands, if not millions, of individual pressed parts.

When working with an overseas supplier, the stakes can be higher. If you’ve waited weeks for a shipment to arrive, it won’t be easy to send them back – perhaps leaving you to complete the re-work in-house, or finding an alternative supplier who can complete the job instead.

Although many overseas suppliers may offer reliable project management, it is far from guaranteed. Language differences can present a barrier to discussing complex technical issues or detailed exchanges, with misunderstanding or misinterpretation contributing to batches that don’t meet your expectation.

Working with a UK supplier can ultimately protect the quality that you require and prevent unpleasant surprises on delivery; as well as ensuring that any issue can be quickly and easily resolved.

4. End-to-End Solutions

Do you consider an overseas manufacturer to be a supplier or a partner? If you’re not involving them from the design stage onwards, it’s likely to be the former – and you’ll be missing out on a host of benefits.

Overseas suppliers are, as discussed previously, often sold on price. They take your design, produce it and ship it – they aren’t considered to be in a position to go the extra mile.

When you give complete visibility to a local supplier, you also give them the opportunity to optimise each element of the production cycle. They can help you to choose the perfect materials and shipping options before production even starts.

For example, Clamason have seen an increasing need from OEMs to take the heat out of electronics. By being involved in the production of pressed components from the very start, we were able to help create solutions such as complex aluminium heatsinks, which are now used in a range of different consumer products.

Through a closer partner relationship, production can be elevated with an end-to-end solution that’s proactive – not reactive – and create far more innovative results.

5. Real Value

When you’re offered a very low-cost service from an overseas supplier, those savings need to come from somewhere and it tends to be the quality of production that suffers.

Choosing a local supplier may be a bigger investment upfront but when it translates to high-quality components that you can trust, you can be confident that you’re protected from hidden expense.

Clamason offers a closed-loop method of production that allows projects to be streamlined for the most cost-effective output – without compromising on quality. Meanwhile, you’ll experience minimised exchange rate exposure when compared to shipping from overseas.

When combined with a reduced risk of freight delays and creeping shipping costs, you’ll benefit from an investment that results in real value for the sort and long-term.

Clamason have more than seven decades of experience in stamping metal pressings for electronic components.

Clamason currently run two production sites – our UK manufacturing base in the West Midlands and an additional plant in Nitra, Slovakia which enhances our distribution efficiencies across Europe. Both locations manufacture highly complex parts for a variety of applications, using leading-edge equipment that can produce components in their millions.

If you’re looking to manufacture a new or enhanced electrical component from a metal pressing, why not have a chat with us about your needs? Our experts will be happy to help.