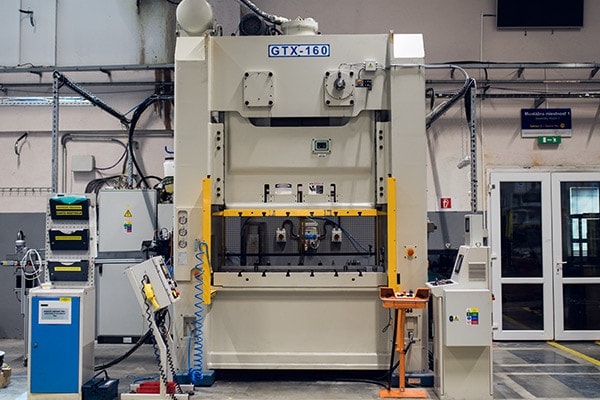

Advanced manufacturing of key metal components for EV and Hybrid Vehicle As one of Europe’s leading manufacturers of automotive pressings, Clamason Industries strive to give our clients a competitive advantage through manufacturing excellence. We have invested heavily...