Clusters

Precision Metal Stamping for Automotive Digital Instrument Clusters

Digital instrument clusters offer a number of advantages over traditional analogue gauges and, a result, are fast becoming the expectation in modern vehicles.

Instead of physical dials and needles, digital instrument clusters use screens to display information such as speed, fuel level, engine temperature, and other vehicle parameters.

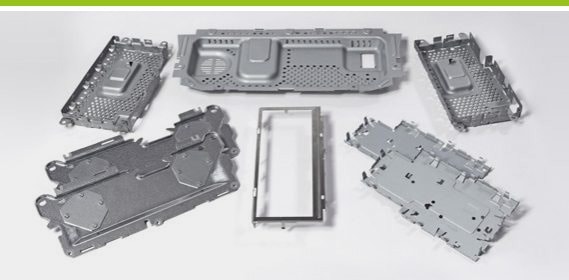

Metal pressings are a key component in the manufacturing of automotive digital instrument clusters, as the stamping process can be used to create a wealth of complex shapes and designs – which are then finished and assembled into the final product.

Clamason are experts in the production of pressed metal instrument clusters – including rear housings and heat sinks.

Due to the nature of electronic housings, weight reduction and cooling features are a crucial design consideration. In many cases, Clamason has re-designed cast or extruded heat sinks as pressed parts, providing automotive manufacturers with the benefit of increased tooling life, as well as significant cost savings.

- Designed to prioritise weight reduction and cooling features

- Bespoke innovations to reduce cost

- Optimising tooling life

- Manufactured in steel, aluminium and stainless steel

- Material thicknesses ranging from 0.2mm to 1mm