Drug Delivery Components

300m+ manufactured per annum

Empowering Healthcare Innovations with Precision Engineering

At Clamason, we’re driven by a commitment to excellence and innovation in the medical sector.

With decades of experience in metal stamping, we specialise in the production of critical components that advance medical care and all-important patient safety.

Medical Devices: Precision Manufacturing for Healthcare Needs

On the front line, healthcare never stands still. It’s this constant, urgent pace which underpins product development across all medical disciplines. Clamason supports this continuous evolution with its state-of-the-art precision pressings for drug delivery components – manufactured to exact specifications, at pace and ready to scale.

Our facilities in the United Kingdom and Slovakia are extensively equipped to meet the complex demands of the healthcare industry, producing more than 300 million high-quality medical device components annually.

Why Choose Clamason?

- Accredited Excellence. Achieving ISO13485 accreditation in 2008, we have established ourselves as a key supplier in the medical device sector, specialising in components for drug delivery devices such as insulin pens and dry powder inhalers.

- Product development. The team have extensive experience in providing customer design for manufacture advice utilising 70+ years of experience. In addition, Clamason can provide production representative prototypes giving clients the ability to realistically perform testing prior to launching production tooling.

- Precision and Quality. Our commitment to precision is unmatched, with components crafted from premium stainless steel, via advanced Bruderer presses delivering speeds up to 1000 parts per minute. Rigorous inspection processes, including 100% camera checking and batch verification, ensure the highest quality.

- Comprehensive Solutions. From thorough cleaning protocols to tailored packaging solutions, Clamason offers end-to-end services to take your medical device project from concept to completion.

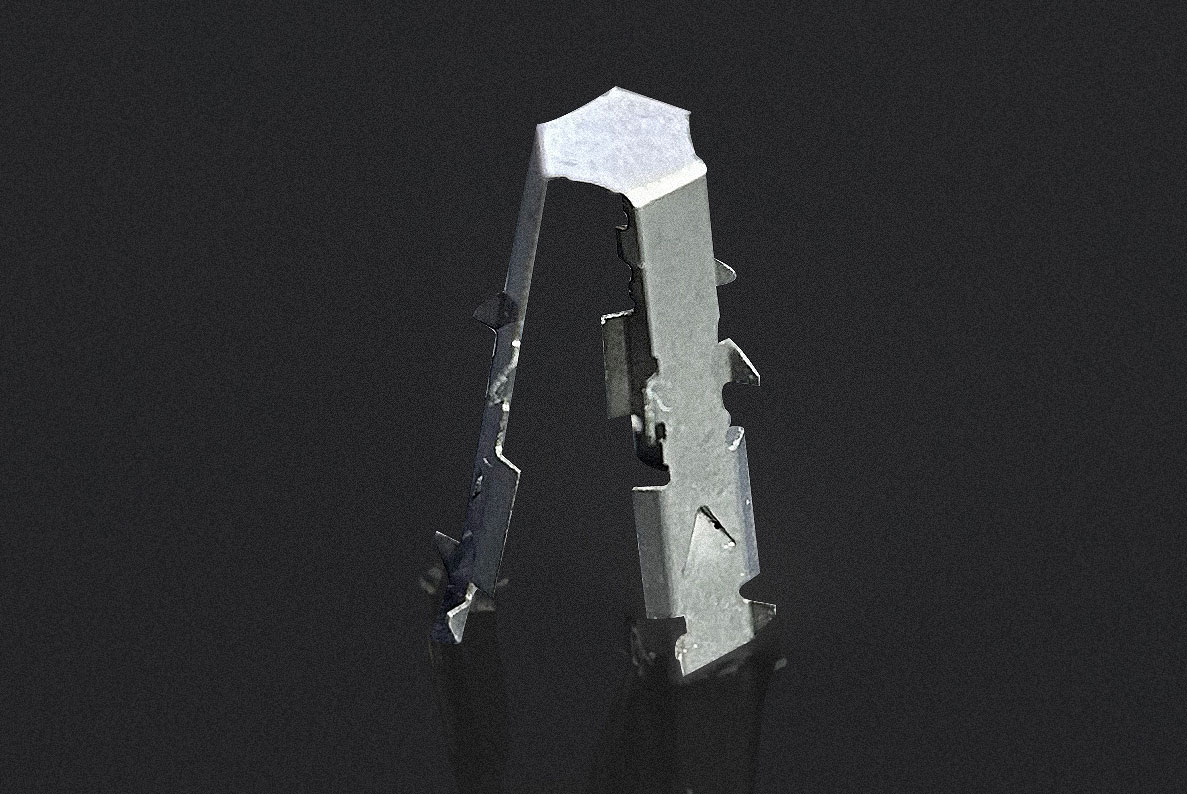

Rigid Needle Shields (RNS): Safeguarding Healthcare Practices

Clamason is a leading manufacturer of RNS remover components, with 5 different variants prototyped and in commercial manufacture. These essential components – made from stainless steel and approximately 0.2mm thick – play a crucial role in auto injector development and functionality.

Innovative RNS Solutions

- Bespoke Designs. Recognising the diverse requirements of healthcare devices, we offer flexible RNS Remover solutions, accommodating different sizes and designs.

- Agile Manufacturing. Our unique three-phase approach, from prototype to full production tooling, ensures versatility and efficiency in meeting specific client requirements.

- Collaborative Expertise. Clamason’s team is adept at working with a range of shield designs, offering end-to-end support from initial design to commercialisation.

Why Partner with Clamason for RNS Production?

- Accredited Reliability. Our ISO13485 and in-house validation expertise

- Customisation and Flexibility. With extensive experience in medical-grade metals and precision stamping, we provide tailored solutions that meet the unique needs of each project.

Choose Clamason Industries for Drug Delivery Components

At Clamason, we do more than just manufacture components – we innovate solutions that contribute to safer, more effective medical care. Our expertise in drug delivery components, combined with our commitment to quality and precision, makes us the ideal partner for your next project.

Contact us today to discover how we can support your healthcare innovation goals.

Case Studies

Fire plates, Part of a Life Saving Device for the Construction Industry

Introduction Clamason Industries, a leader in precision metal stamping and assembly, began their collaboration with ViperClip to help develop a vital fire safety component for the ViperClip system. The ViperClip, an innovative cable fastening solution designed by...

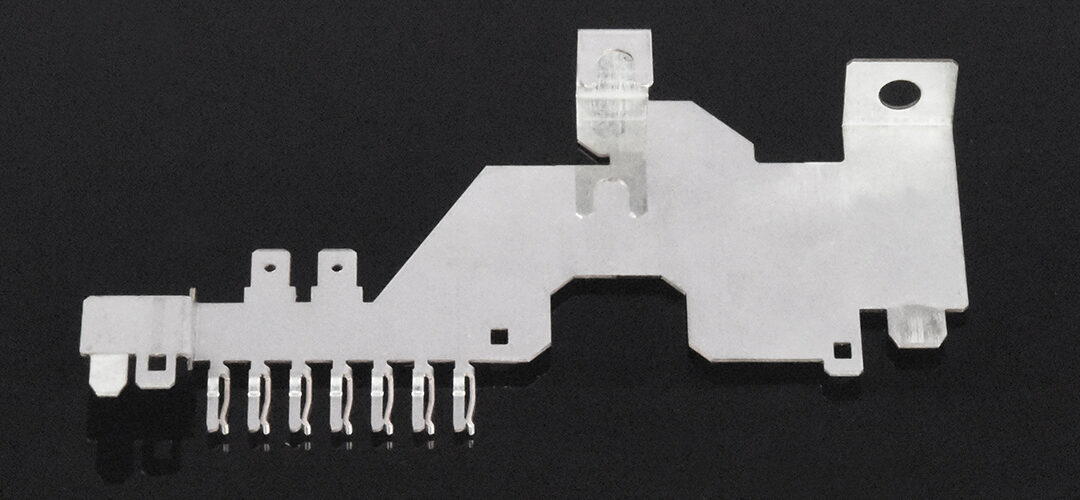

Clamason Help Blue-Chip Manufacturer Restore Production Cycle

The Challenge During the height of the COVID-19 pandemic, a major blue-chip manufacturer of electrical assemblies found themselves in difficulty. Their usual stamping solution was no longer fit for purpose, with technical and supply issues blighting the production...

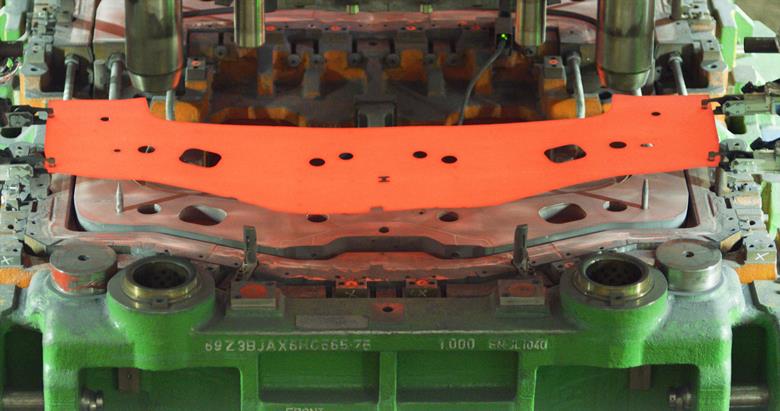

Advanced High Strength Steels (AHSS)

Taking Shape Most advanced-high-strength steels (AHSS) materials comprise specific chemical compositions and microstructures, with a number of strengthening mechanisms used to boost strength, ductility, toughness and fatigue properties. While such characteristics are...

Solvent Degreasing Works for Clamason

Pero degreaser meets SED legislation & slashes solvent use at volume pressings manufacturer Established 60 years ago, Clamason Industries is a highly service-orientated, independent UK manufacturer and assembler of precision pressings serving a broad spectrum of...

Latest News

Metal Cleaning & Contract Services Infographic

Thin Gauge Stainless Steel Pressing: Is It Right For Your Project?

Thin Gauge Stainless Steel Pressing: Is It Right For Your Project? Manufacturers working in the medical, automotive, electronics and consumer goods sectors use thin gauge stainless steel primarily because it provides strength along with formability and corrosion...

How Does High Precision Metal Pressing Improve Accuracy?

In industrial sectors where even the smallest deviation in precision can jeopardise safety, functionality, or performance, manufacturing accuracy is vital. This ability to maintain quality and consistency is especially relevant in...

Ensuring Regulatory Compliance in Metal Stamping for Medical Devices

Stamping Regulations Metal stamping, a key process in the production of medical devices, must adhere to stringent regulatory standards to meet industry requirements. Here we will examine the importance of regulatory compliance in metal stamping for medical devices,...

Discover more about our Metal Stamping and Presswork for Automotive Industry