Design

Design / CAD Services

Finding the ideal solution always starts with getting a clear understanding of the problem. Clamason’s UK Design Centre in Kingswinford has a specialist team of engineers who use their knowledge and experience to design bespoke metal pressing solutions to suit client needs. Whether it’s a brand-new design for manufacture or a redesign to improve an existing component’s performance, the designers will review what’s required to create the best result.

Each project follows a comprehensive design and value-engineering process. Our CAD services Utilise industry-leading software and validation/testing methods, the designers review which design and manufacturing methods will achieve the best functional performance.

As well as ensuring the design maximises value and reduces costs, the exercise will also identify what materials and finishes should be used, before a finished 3D design is created for the client to review.

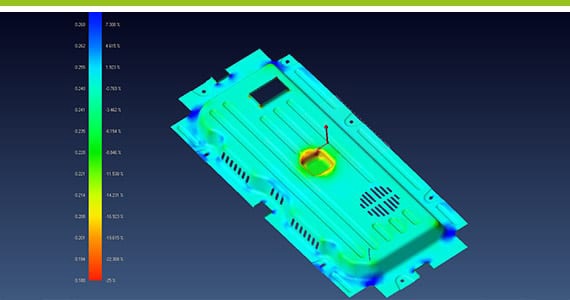

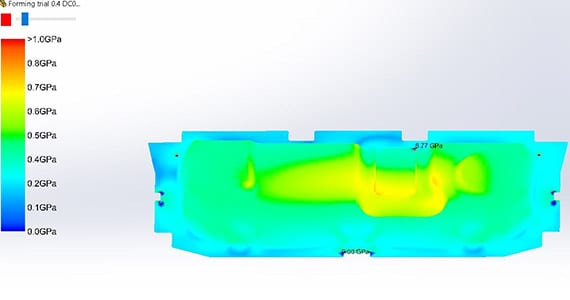

In order to reduce development time and materials cost, a pressing simulation is created. The simulation results allow the designers to replicate the effect of the pressing process on the components design and specified raw material which could result in a change to the component design. There is also the opportunity to simulate different raw material specifications before the production tooling is manufactured.

Once a design is finalised, a fully detailed drawing can be produced to allow a prototype to be manufactured. Clamason works with a number of trusted local and international manufacturers to produce prototype components, within a relatively short lead time, that can be tested thoroughly before any series production is planned. In addition to our CAD services, Clamason Industries offer a wide range of high quality capabilities ranging from technical cleaning through to supply chain and logistics – click here to view.

- Bespoke metal pressing solutions to suit client needs

- Brand new designs or enhancements to existing components

- CAD services using industry-leading software

- Maximising value and reducing costs

- Optimum processes & materials identified for client before production

- Short lead times … excellent results!

- Feasibility & performance accurately analysed before production

- We work with a number of trusted local & global manufacturers