Sustainability at Clamason

Committed to a 25% Reduction in Our CO2 Output

Manufacturing is essential to drive innovation in product development. However, this shouldn’t be at the cost of our natural resources. That’s why the team at Clamason are committed to shrinking the carbon footprint of our industry, by using leading-edge advancements in more sustainable ways.

Sparking A Change by Reducing Our Use of Power

Heating our factory and its water supply used to use huge amounts of gas, while powering equipment would guzzle electricity. We’ve put a stop to that.

Sustainability Practices

We’ve brought eco-friendliness into every day by using renewable energy sources, implementing energy-efficient equipment, and reducing waste through recycling and composting.

Driven to Adapt

Our fleet is going electric. Our diesel company cars have already been replaced by EVs – while our diesel vans are being phased out in favour of battery-powered alternatives, too.

By upgrading our boilers and heaters to next-generation, A+ efficiency eco heaters, our gas use on the shop floor has been greatly reduced

We’ve also installed destratification fans and linked heating control into a centralised system, where all thermostats can be monitored from one place – offering improved heating management throughout the entire factory.

This centralised system is more intelligent than most. It even features a ‘learn’ function, allowing it to activate when our teams arrive for work, and power down when they leave – creating all-new efficiencies in our working day.

Most Energy-Hungry Manufacturing Comes from Air. So, We’re Feeding Ours with Eco-Friendly Compressors

Compressed air is our main use of power. We’ve slashed its use by 26% in just two months.

We generate our own compressed air, that we can switch on and off as needed – as opposed to having a continuous supply. This includes using valves on machinery which will automatically turn off, without needing manual intervention.

View Our Carbon Footprint Declaration Here

Sustainability info graphic

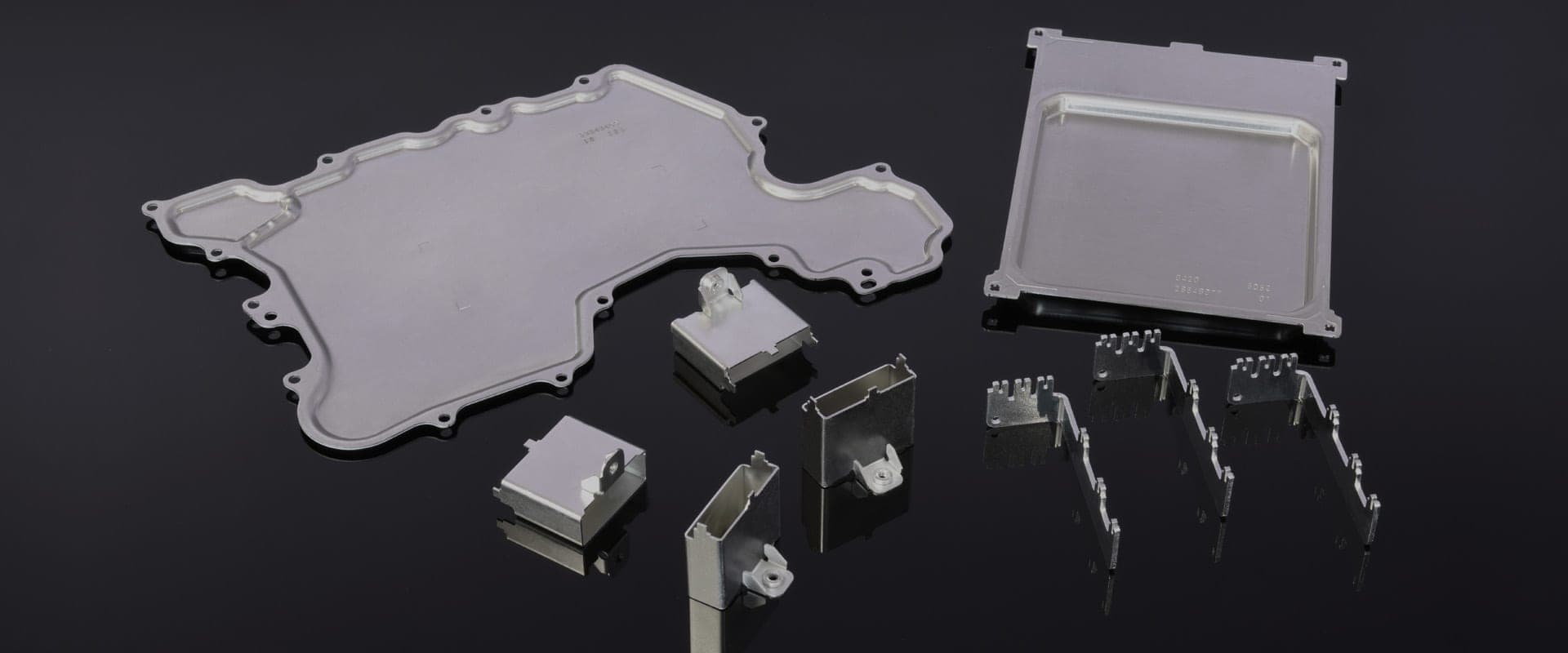

Key projects to help reach these targets:

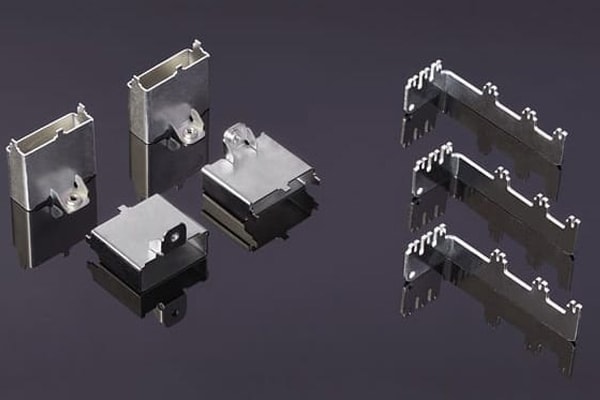

Eco-Tech

E-Mobility

Electrification & Hybrid