Press or Die

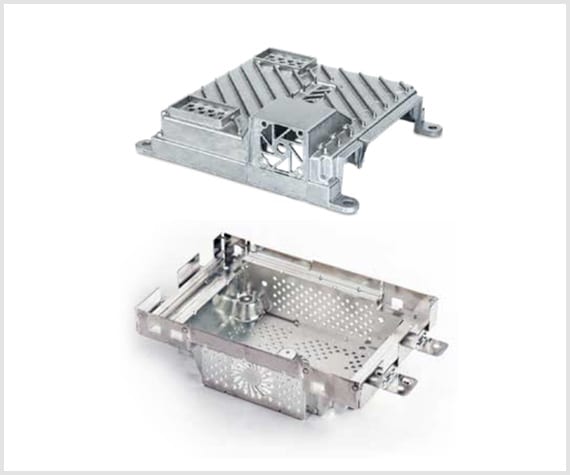

One of our customers recently approached us with a casting and asked if we could manufacture a stamped equivalent.

Our technical team love a challenge and delivered a fantastic alternative. Several benefits to changing are: Weight Saving, Tool Life Increase, Positive Environmental Impact & of course Cost Savings.

So why change? ….

Cost Effective Metal Pressings

Cost

Lower cost per volume, faster production, less scrap material.

Production

Production rates up to 1000 parts per minute on small presses & 60 parts per minute on larger machines.

Energy

Press manufacturing can be up to 75% more energy efficient against that of the cast manufacturing process.

Labour

With stamping you have the ability to produce a finish part with no 2nd operation or machining required to achieve the required tolerances.

Tooling Life

Press tools will last 5,000,000 shots in comparison to cast which will last 100,000 before replacement or maintenance is required.

Efficiency

Press manufacturing efficiency

Manufacturing of metal pressings can be up to 75% more efficient than that of casting production.

Faster Part Production

Press parts can be manufactured in a 10 part to 1 ratio against that of the cast equivalent.

One operation finishing

Not always a need for a second operation.

Cost-effectiveness from tooling costs to piece price.

Matched effectiveness.

Environmentally friendly manufacturing.

The pressing process is so much more flexible when it comes to design, the finer details, complex shapes and the overall process:

Let us review your current cast parts and formulate an alternative solution that could potentially be of massive benefit to your company. Clamason Industries – manufacturers of quality metal pressings!

Click the button below to download “Press or Die” metal pressing presentation: