Clamason’s new range of components are helping to move towards a cleaner and greener future in key global industries.

Electrical Mobility & Vehicles

E-mobility is on the rise with the use of fully-electric, hybrid and hydrogen fuelled vehicles. Electric vehicles such as e-bikes and electric cars are seen to be more environmentally friendly in a number of ways.

Firstly as electricity is a cleaner source of energy, it reduces the burning of fossil fuels and hydrocarbons contributing to global warming. Electric vehicles are also quieter and emit less traffic “film” (dirt which can be very expensive to clean and looks unsightly).

We have invested heavily to support our customers within the electrification and hybrid sectors of the automotive industry. Clamason produce a range of aluminium covers for inverters which can manufactured between 0.5mm and 2mm thick and can be produced on presses up to 300 tonnes, with industry leading part cleaning standards allowing customers to specify less than 100um particles sizes. More information on the new ATC100 cleaning investment will be coming in the following weeks.

We also have significant experience in producing busbars and shields for electric vehicles. Busbars are generally made from copper with a tin coating and our shields are made from either tin coated steel or stainless-steel dependent on the application and volume.

Clamason also produce one of the key structural components which holds the motor and pedal assembly together on e-bike frames. The component is made out of aluminium … so it is lightweight, with its strength coming from the component design which can be produced in high volumes to meet the seasonal demands of this product type.

Power and Distribution

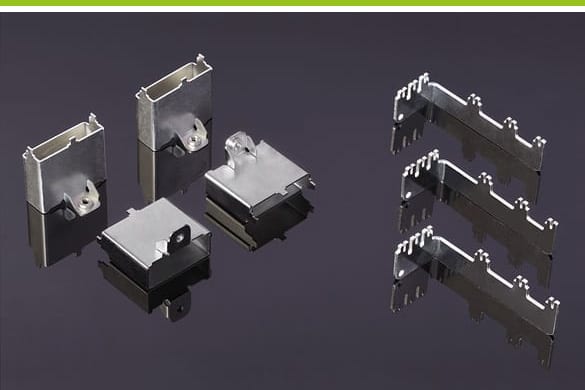

Clamason has a long history in producing components for the power and distribution industry, from simple press parts in steel through to multi-part sub-assemblies that can be seen in power distribution boards in factories, hospitals and schools.

As volumes range from 1000 to 1 million per annum, the components are produced on various types of equipment, from single operation presses up to high-speed Bruderer presses.

This flexibility has already provided environmental benefits, with one of our major customers transferring production of over 150 tools from other suppliers to ourselves, reducing their emissions involved in transportation and logistics of the components.

Our components are also manufactured with longevity in mind, with many lifecycles being more than 20 years – helping to reduce waste.

Clamason has over 70 years’ experience produce bespoke precision metal components for our customers in a diverse array of sectors, including automotive, medical and industrial. If you would like to discuss your requirements then please contact us using our online form.